ERX145

For Inline Coil Coating Measurements

- Takes 45:0 measurements in the lab or on the production line

- Connects with ESWin QC to monitor color quality

- Offers a 60mm measurement distance and 30mm measurement spot

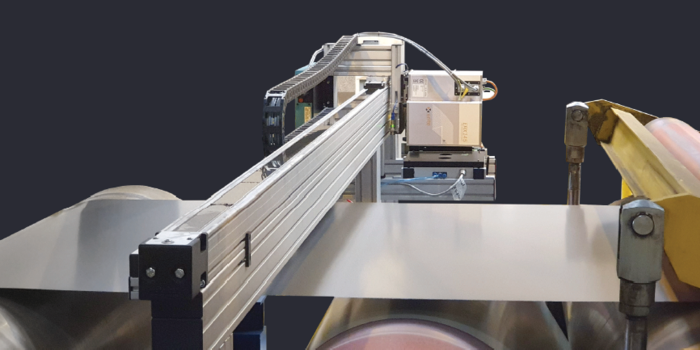

Monitor Color Accuracy on the Coating Line

Designed to take non-contact measurements on coil coating, the ERX145 can eliminate costly production line color errors, especially in environments with frequent color changes. When paired with ESWin QC software, the ERX145 becomes an inline quality control system that warns operators of color shifts and enables color adjustments.

Keep the Coil Coating Line Moving

With a 45°:0° measurement geometry, the ERX145 Inline can be mounted on a traversing beam over the production line to recognize a color shift early, before the roll is ruined. When paired with ESWin QC software, it provides actionable guidance so operators can make immediate corrections without stopping production. It offers excellent correlation to the ERX45 Lab spectrophotometer and objective evaluation according to accepted international standards to ensure the integrity of inline measurement programs.

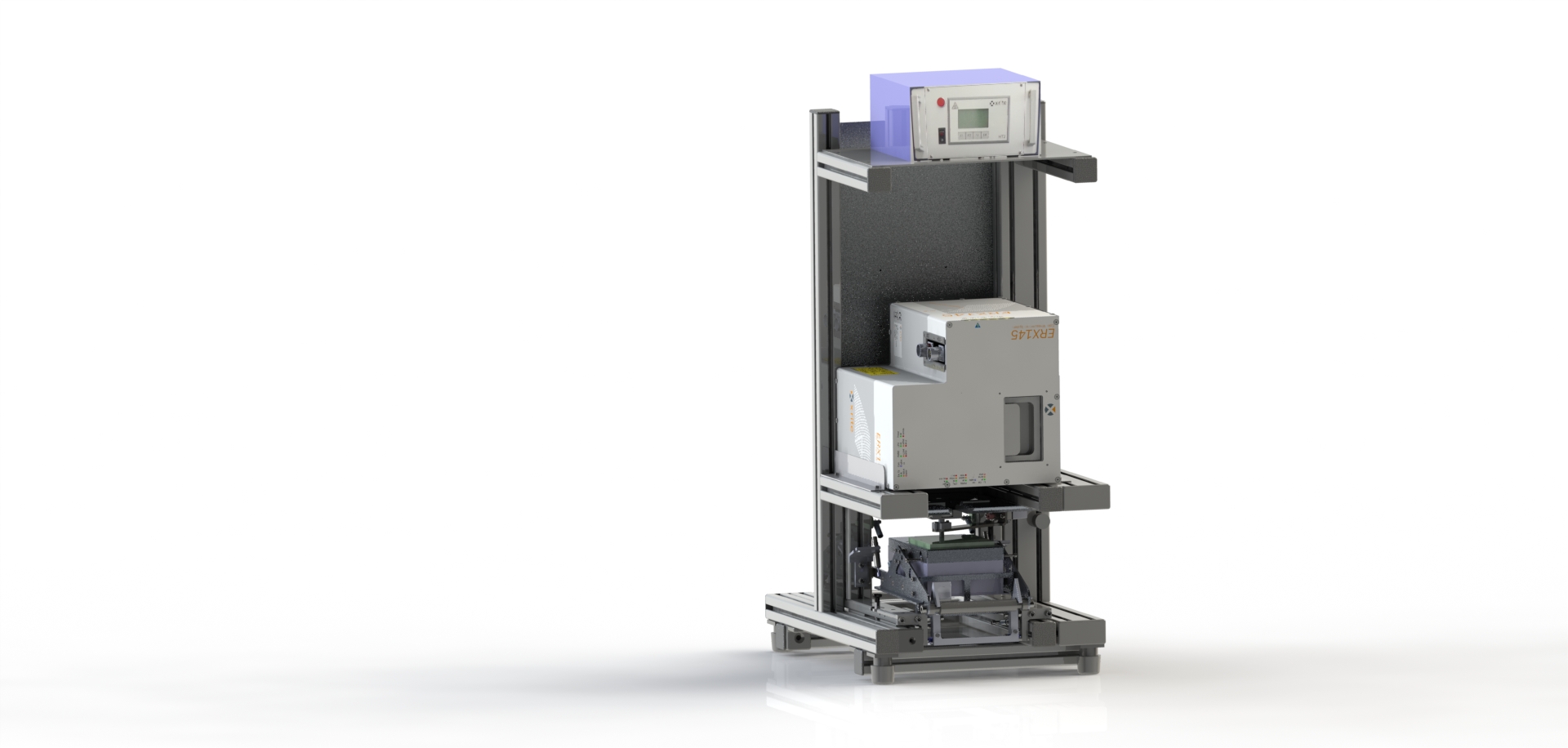

Measure Color on Hot Coated Surfaces

The ERX145 Inline is installed behind the water quench where the product is still hot. The built-in pyrometer measures the actual temperature of the hot strip and, along with ESWin QC software, recalculates the color to room temperature so that the inline measurement shows an excellent correlation to the laboratory system. If necessary, the GlossFlash 6060 can be mounted next to it to evaluate color and gloss across the entire length and width of the coil. If the color of a strip is important on both sides, a second ERX145 Inline can be mounted below the roll, too.

ERX145

Specifications

Support

Resources