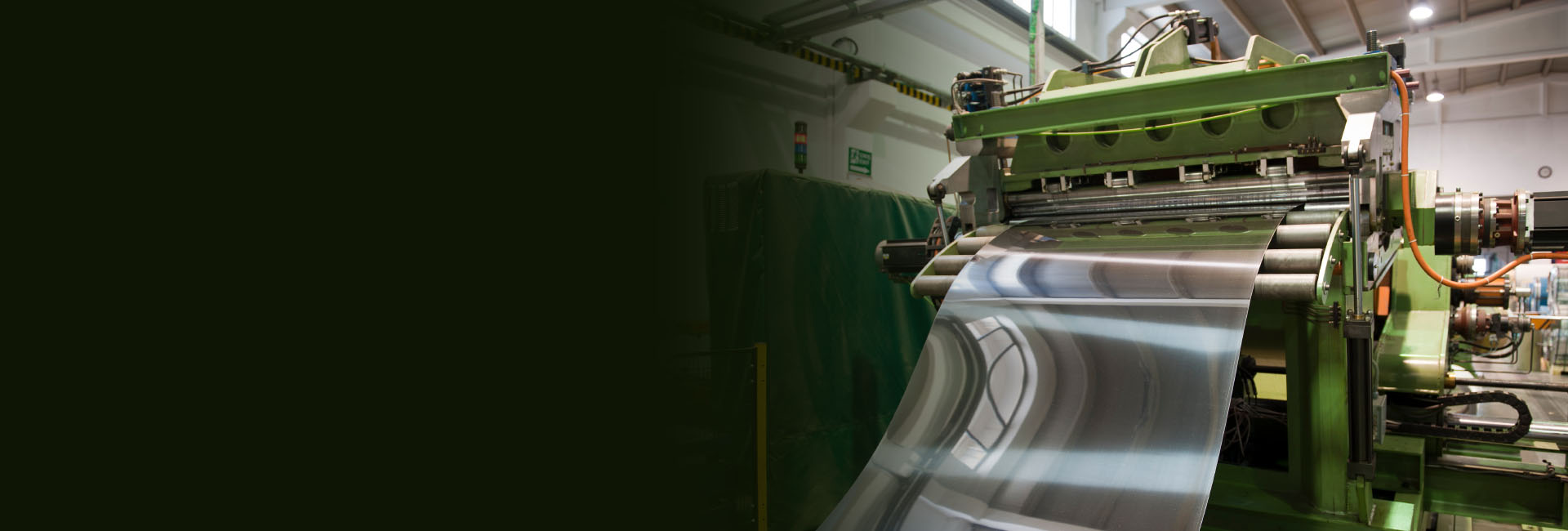

Coil coating paints metal in sheet form for superior, durable results in much less time. However, any shift in color or gloss on a fast-moving production line can quickly create a lot of waste. An inline color control solution can monitor color quality and ensure consistency in real time to avoid costly rework.

Challenges

Each step of the coil coating process is critical to producing superior results, however the process itself can affect color quality and consistency.

- Temperature fluctuations during production can impact color

- Paint, powder, and film thickness can vary during spray fabrication

- Oven temperature and curing times can impact color and adhesion

- A continuous pass production line can quickly waste a lot of product if color shifts

Coil Line Color Control Methods

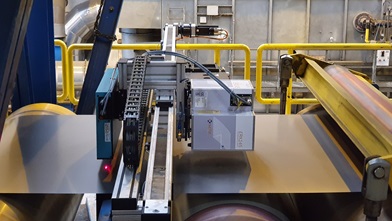

An inline color control solution helps coil coaters ensure powder coating color stays within tolerance from color specification through final QC on the coil coating line. In the lab, a benchtop spectrophotometer and software are used to define the color standard. During production, non-contact spectrophotometers fitted on a custom traversing beam continually measure color and gloss on hot, glossy, matte, grained, uneven, and embossed surfaces at a safe distance from the coil to avoid damaging the product or device, even under the most severe conditions. The inline spectrophotometers take continuous measurements with a high degree of accuracy to identify if temperature fluctuations during production will impact color and correct measurements with thermochromism control. If a color tolerance is exceeded, operators are alerted so corrections can be made immediately. To ensure the integrity of the program and identify areas of improvement, color quality records are documented according to accepted international standards.

An inline color control solution helps coil coaters ensure powder coating color stays within tolerance from color specification through final QC on the coil coating line. In the lab, a benchtop spectrophotometer and software are used to define the color standard. During production, non-contact spectrophotometers fitted on a custom traversing beam continually measure color and gloss on hot, glossy, matte, grained, uneven, and embossed surfaces at a safe distance from the coil to avoid damaging the product or device, even under the most severe conditions. The inline spectrophotometers take continuous measurements with a high degree of accuracy to identify if temperature fluctuations during production will impact color and correct measurements with thermochromism control. If a color tolerance is exceeded, operators are alerted so corrections can be made immediately. To ensure the integrity of the program and identify areas of improvement, color quality records are documented according to accepted international standards.

Color Quality Benefits for Metal Coaters

An inline coil coating color control system offers fast ROI, usually within 6 months.

An inline coil coating color control system offers fast ROI, usually within 6 months.

- Reduces primer and powder coating costs, waste, and rework

- Catches color issues early, saving a modern coating line ≈$50,000/month

- Offers visibility to all stakeholders and tracks results for a revenue increase of ≈5%

Coil Coating Process Color Control

- In the lab, the color standard is measured at different temperatures with the ERX145 mounted on a heating table to replicate thermochromism control on the machine.

- The color standard and allowable tolerance is shared across the network, including workstations in the production control booth, at the color coating line paint system, and at client sites, so everyone has visibility into the process.

- The production machine receives process data through the network to automatically start the new job.

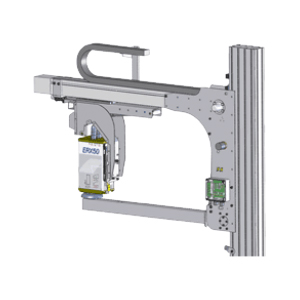

- Once the coil coating process begins, the ERX145 and, if necessary, the GlossFlash 6060, move on a traversing beam to evaluate color and gloss across the entire length and width of the coil without slowing or stopping production.

- Color measurements are tracked in ESWin QC software and real-time results are shared with users across the network. When a color tolerance is exceeded, the operator is notified, and a correction is made before any product is wasted.

- Quality records ensure adherence to international standards and track continuous improvement.

Coil Coating Color Measurement Products

ERX145 Spectrophotometer

Ideal for measuring color on large surfaces on a modern coating line, this non-contact benchtop and inline spectrophotometer has a 30mm aperture, wavelength interval of 330 nm to 730 nm, and optical resolution of 1 nm. It offers excellent inter-instrument agreement and monitors dirt and temperature to identify thermochromaticity. Built for use in harsh production environments, it is durable and offers excellent short- and long-term stability.

GlossFlash 6060 Gloss Meter

A non-contact inline gloss meter that provides the gloss value directly at the top coating for coil coating production environments. Its modular design offers maximum flexibility for use with other inline color measurement components, including the ERX 145 for color measurement and ESWin software for quality control and tracking.

ESWin QC Software

A customizable quality control software solution that works with ColorXRA Lab to make pass/fail decisions for high visibility safety apparel. It presents measurement results in an easy-to-interpret graphic display as well as printed reports for proof of compliance.

Custom Traversing Beam

A customized aluminum frame that can be built to fit any production line and mount the inline spectrophotometer above the web for continuous non-contact measurements from left to center to right.

Achieve Color Success for Coil Coating

An inline color control solution from X-Rite helps coil coaters monitor color quality and consistency in real time for less waste and rework, resulting in a quick ROI and continuous color quality improvement.